열압착 프레스 압력분포 시스템

*This product has been updated to the Industrial Tactarray

PPS의 열압착 프레스 압력 측정 시스템은 열압착 프레스의 접촉 압력분포에 대한 정확한 측정 데이터를 제공합니다.

PRECISION MEASUREMENTS AT HIGH TEMPERATURES

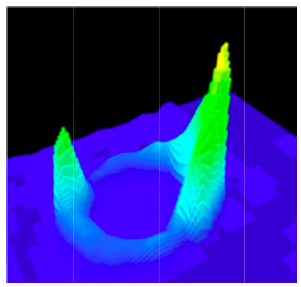

Companies that use a heat press in their manufacturing processes can use the Heat Press Pressure Measurement System to image and quantify the interface between the press and the product at different temperatures to ensure stability and consistency throughout the process. The system can collect usable force/pressure data at actual heat press high temperatures in real time for quick analysis and performance assessment of the equipment in order to improve product quality and yield. Unlike competitive offerings of film-based solutions, PPS’s tactarray sensors provides dynamic real-time visualization for adjustment and alignment of heat press processes. The system’s thermal compensation allows users to capture and relate pressure profile to system temperature. The Heat Press Pressure Measurement Systems provide the convenience and cost-efficiency of reusable system with high-quality, quantitative and repeatable alignment information.

The Heat Press Sensor System includes a single heat press sensor of a chosen design with 1.5m cable. Using the included T4500 interface electronics with USB 2.0 to attach to a computer, the system runs PPS’s Chameleon image capture and analysis software. This industry-leading software is fully featured which means it can export replay, save test data, and perform analysis functions. Chameleon can also record and playback video with your data results for even greater insight and analysis. It also has an Embedded Thermocouple for managing temperature transients.

시스템 핵심 기능과 장점:

Dynamic real-time visualization for adjustment and alignment of heat press processes provides immediate feedback and allows faster adjustments and less machine down-time.

Thermal compensation for accurate data collection allows users to collect pressure data during actual real time production process as temperature of part ramps up to process temperature.

Reusable system with real-time feedback, offering dynamic real-time visualization for adjustment and alignment of heat press processes.

PPS의 정전용량방식 센서 기술을 통해, 재보정이나 반복적인 테스트에 소요되는 시간을 절약하고 결과를 개선할 수 있어 문제를 더욱 신속히 해결하거나 필요한 데이터를 더욱 쉽게 구할 수 있습니다. 기존의 저항방식의 촉감 센서 기술보다 반복성은 두 배, 최소 감지압력은 5배, 정밀도는 50% 더 향상되었습니다.

Chameleon Visualization Software provides intuitive, easy to use, high-quality visualization, and easy access to data for analysis and export to other applications. The software is fully featured which means export, replay, save, and analysis functions are included with every system, unlike competitors who require a paid upgrade for these features.