Purdue Uni Research Project Assesses Lifting Injury Risks using PPS TactileGlove

The Challenge: Improving Ergonomic Risk Assessment for Manual Lifting Tasks

Manual material handling (MMH) tasks such as lifting, lowering, and carrying remain one of the leading causes of workplace injuries, particularly those related to musculoskeletal disorders (MSDs). According to the Liberty Mutual Workplace Safety Index, overexertion from manual lifting consistently ranks as the top cause of disabling workplace injuries in the United States (Liberty Mutual, 2023 Workplace Safety Index).

Historically, ergonomic assessments using tools like the Revised NIOSH Lifting Equation (RNLE) have helped identify hazardous lifting tasks and mitigate risk through changes to job tasks and working conditions. However, RNLE requires trained analysts to manually measure and input task parameters such as vertical and horizontal reach, asymmetry, lifted weight, and force applied. This makes widespread or real-time deployment impractical, especially in dynamic work environments (NIOSH Lifting Equation Technical Report, DHHS (NIOSH) Publication No. 94-110).

The National Institute for Occupational Safety and Health (NIOSH) and leading ergonomists have long recognized the need for more automated, accurate ergonomic risk assessment tools for use in real-world workplace environments. These tools are essential for improving occupational safety, worker well-being and reducing the associated costs of injury claims.

The Collaboration: Purdue University, NIOSH, and PPS

To address this challenge, researchers at Purdue University partnered with the National Institute for Occupational Safety and Health (NIOSH) and incorporated PPS' advanced wearable sensing technology. The study, titled "Computer vision and tactile glove: A multimodal model in lifting task risk assessment," will be published in Applied Ergonomics in 9월 2025 and included co-authorship by NIOSH researchers.

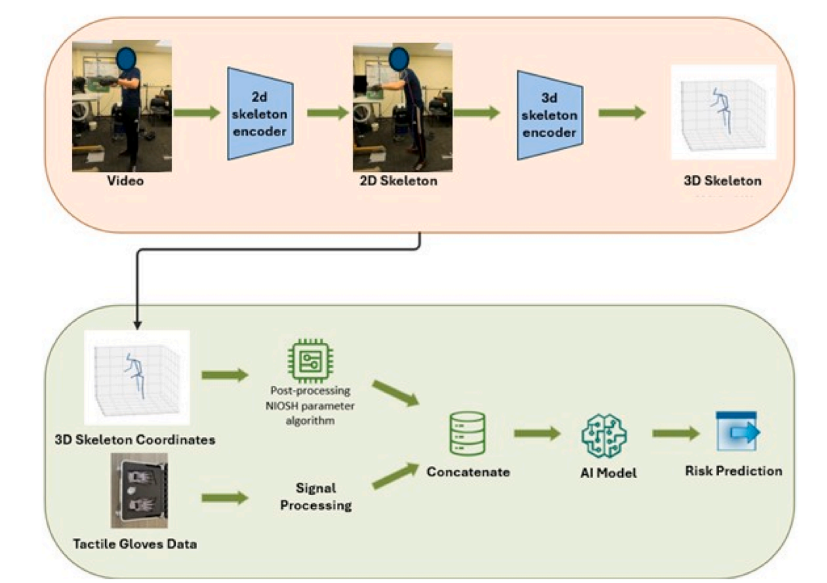

The core objective was to explore a multimodal approach combining computer vision (CV) with PPS' TactileGlove to automatically estimate the lifting index - a key metric in ergonomic risk assessment. This approach allowed researchers to conduct objective evaluations of lifting tasks, using assessment tools that gather objective data across body segments, upper extremities, and body regions.

Innovation: High-Resolution Hand Pressure Data from PPS TactileGloves

At the heart of this solution were PPS TactileGloves, which offer a high-density sensor array (65 sensors per glove) across the palm and fingers. These gloves were selected for their:

Lightweight, comfortable fit, compatible with standard PPE requirements

Wireless Bluetooth data streaming (up to 40Hz) for easy, unobtrusive recording

Participants wore the gloves while performing lifting tasks with boxes of varying weights and heights. At the same time, 3D body movements were estimated from side-view videos using a computer vision models.

The glove measured subtle changes in hand pressure and how force was distributed across the upper extremities. This helped determine how much weight was being lifted and its influence on lifting risk index - two important risk factors in musculoskeletal disorders and injury risks. The system enabled a more complete ergonomic assessment by linking postural data with grip force.

The Experimental Setup: Validating Ergonomic Models with Objective Data

Proposed ergonomic risk assessment method combining body joint extraction via MotionBert (orange) and lifting risk estimation using pose and glove data (green). Adapted from Chen et al., 2022. See full study in Applied Ergonomics (2025).

A total of 31 participants completed 2,747 lifting tasks involving different weights and lift heights. Each lift was captured with:

Pose estimation using computer vision

Direct hand pressure readings via the PPS TactileGloves

The team collected data on vertical and horizontal positioning, lifting distance, asymmetry angles, and pressure across specific hand regions (thumb, fingers, and palm zones). These factors were used to conduct a lifting assessment, ensuring a full analysis of ergonomic risk during lifting.

Researchers applied several machine learning models - including logistic regression, support vector machines (SVM), random forest, and a custom neural network - to evaluate the lifting index and classify injury risk levels (low, moderate, or high).

The Results: Multimodal Model Outperforms Traditional Assessment Tools

The best-performing model used both glove and vision data. It achieved:

✔️Significant gains over single-modality models with 89% classification accuracy

✔️Precision scores of 0.97 (low risk), 0.88 (moderate), and 0.80 (high)

PPS TactileGlove data performed especially well in identifying lower-risk tasks, while posture-based features improved injury risk detection in more complex movements. When combined, the multimodal approach offered a stronger ergonomics process for classifying risk and informing health and safety decisions.

Further analysis revealed that sensors on the middle and index fingers of the dominant hand contributed most to prediction accuracy. These insights align with common grip dynamics in manual lifting tasks, demonstrating how PPS TactileGloves can capture realistic, actionable data.

"Our work shows that glove-based measurements can be a potential new tool for predicting of injury risks during manual lifting when combined with computer vision. This opens the door for smarter, scalable ergonomic assessments for improving workplace safety.” - Dr. Denny Yu, Purdue University

Real-World Applications: Scalable Ergonomic Assessments for Safer Workplaces

The study’s outcomes have practical implications for anyone responsible for workplace safety, occupational health, and ergonomic assessments:

Identify ergonomic risk factors and awkward postures during job tasks

Evaluate lifting tasks and equipment with objective assessment tools

PPS TactileGloves and video capture offer a non-intrusive way to gather objective data in real-world work environments. These tools can be used to improve working conditions, refine practices, and reduce the risk of work-related musculoskeletal disorders (MSDs).

The solution is also ideal for safety training programs, helping teams deliver direct feedback, measure progress, and support workers with personalized ergonomic guidance.

The Impact: Purdue-NIOSH Research Advancements in Ergonomics and Safety

This collaboration between Purdue University, NIOSH, and PPS demonstrates how validated ergonomic assessment tools can improve occupational safety, reduce MSD risk, and contribute to better workplace health. Applications include:

Occupational health evaluations & workplace injury prevention programs

Health and safety reports supported by objective data

By applying research-based technology, employers and safety teams can better determine risk levels, evaluate injury causes, and implement changes that support long-term worker well-being.

Conclusion

What began as an academic exploration grew into a practical collaboration - one that validated the role of wearable sensing and AI in improving workplace ergonomics. By combining PPS TactileGlove data with computer vision, this study not only advanced the field of ergonomic risk assessment but also demonstrated the power of an objective evaluation tools in identifying injury risk, improving workplace safety, and supporting the health of workers.

Are you ready to transform your ergonomic assessments with real-world data and next-generation tools?